USE CASE: HOW WINERGY’S DIGITAL GEARBOX OPTIMIZES A WIND FARM IN THE US

Globally, the requirements for wind farm maintenance are becoming more and more specific. The actual lifetime of a turbine can be shorter or longer than the expected 20 years based on the operating conditions at each site. The same applies to the gearbox. This opens opportunities for performance optimization. By the help of Winergy’s Digital Gearbox wind farm owners can be empowered to predict the Remaining Useful Lifetime (RUL) of their gearboxes in order to safeguard functional performance, optimize maintenance planning and reduce costs. Winergy and Siemens PLM Software developed an approach to estimate the gearboxes’ RUL for a whole wind farm by combining historical wind data, a digital twin of the gearbox as well as design and material properties of the rotating gearbox components.

Goal: Output maximization

- Enable power uprates of gearboxes

- Identify necessary power derates

- Detect unknown and unwanted abnormalities

- Avoid drive train overloads

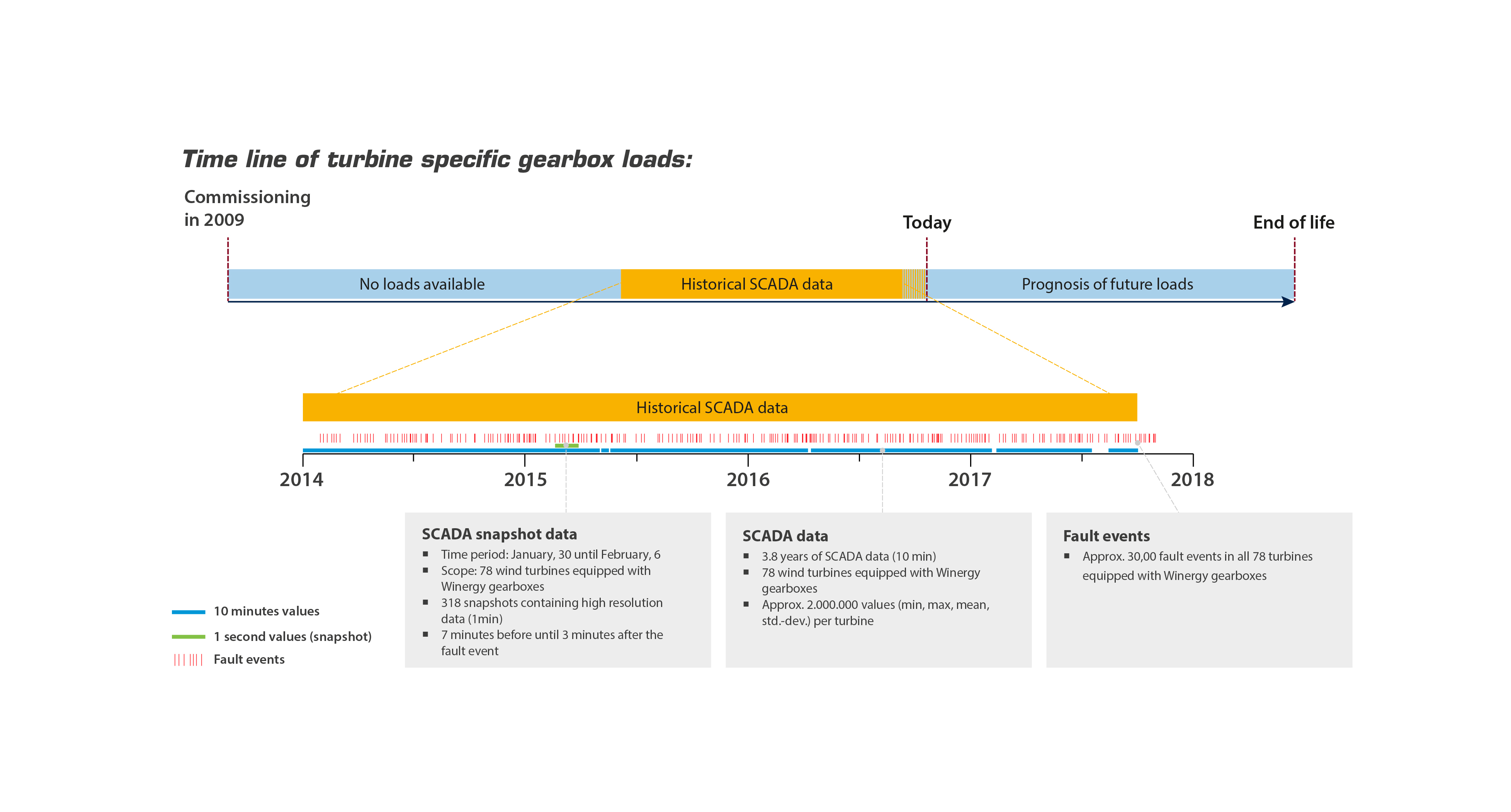

PILOT PROJECT: SCOPE AND DATA BASIS

The project scope included a reliability analysis of 78 Winergy gearboxes in 1.5 MW turbines in an US wind farm, commissioned in 2009. The focus was on gears and bearings. Winergy executed this project in collaboration with Siemens PLM Software and the wind farm owner.

Targets:

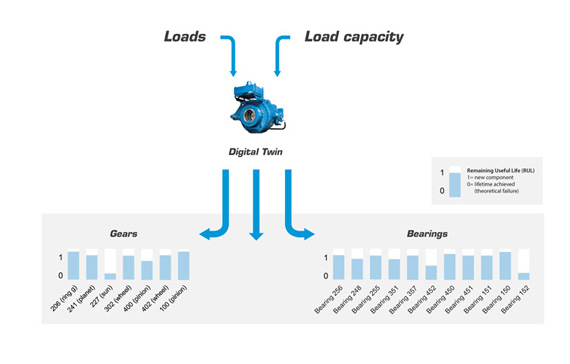

- Remaining lifetime prediction of gears and bearings

- Early gearbox failure prediction based on SCADA data

- Lifetime extension based on real (measured) turbine data

Due to specific loads during the lifetime of the gearboxes different types of data were considered: High-resolution load cases were generated and evaluated with the help of SCADA data and a MKS model (multi-body simulation). These data are the basis for the theoretical lifetime calculation.

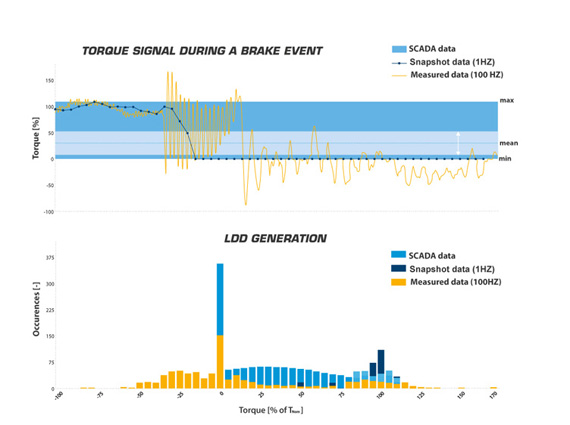

During wind farm operation high dynamics and volatilities are usually not captured precisely within SCADA data, which is not enough to predict the actual loads and utilization of the gearbox. In order to reliably assess the loads occurring at the gearbox, it is necessary to measure the actual torque, e.g. with Winergy’s Torque Sensor.

This data serves as basis for the creation of a digital twin of the gearbox. Real loads on the gearboxes in the turbine operation and the load capacity (defined in the design phase of the gearbox) are compared. The digital twin enables RUL calculation of the gearbox and major components. It also offers the chance to predict failure and reduce O&M costs.

PROJECT SPECIFIC RESULTS

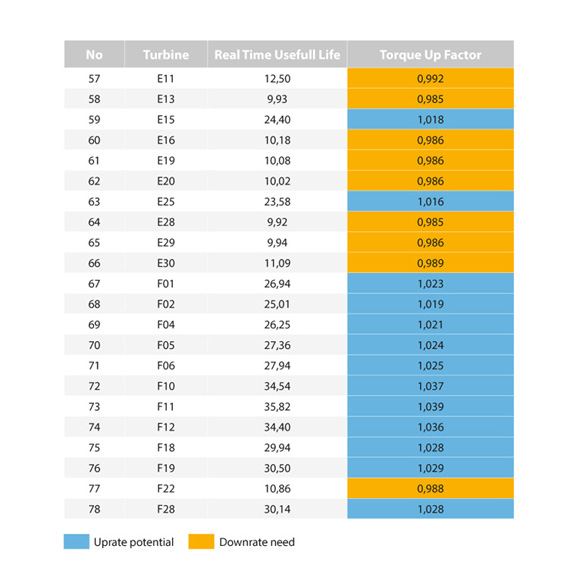

With regards to the considered 78 1,5 MW wind gearboxes, an additional energy production potential of around 90,000 MWh over total lifetime can be realized. For this purpose, 52 gearboxes can be uprated by up to 3.9 percent thanks to hidden reserves, 26 gearboxes need to be downrated by up to 1.9 percent due to overloads which were unidentified before.

Furthermore, O&M costs decline since RUL analyses allow the early detection of potential failures. Counter measures and low-cost service measures (e.g. endoscopy) can be carried out in good time to prevent larger failures.

SUMMARY & OUTLOOK

For an accurate RUL calculation, real mechanical torque data is required in addition to SCADA data. This can be achieved either by the help of a validated MBS model or by torque sensor data. Winergy offers this torque sensor with highest accuracy alongside with analytics.

Opportunities to reduce LCOE (Levelized Costs of Electricity):

- Annual Energy Production (AEP) upside potential

- OPEX potential: failure prediction and prevention by means of suiting O&M measures

- Long-term potential to use improved drive trains per location and wind farm: Best combination of different drive trains in one wind farm depending on the location (and connected loads) of the individual turbine

Acknowledgements:

- Siemens PLM Software: Bonnet, P.; Dekkers, R.; Hendicx, W., Vandermeulen, W.

- Winergy: Egeling T.; Hidding, E.; Hövelbrinks, N.; Endemann, D.; Uhlending, M.

In case of further questions, do not hesitate to contact us.